If you’ve recently detected a burning smell coming from your clothes dryer, it’s important to investigate this issue immediately to prevent potential fire hazards and ensure the safety of your home. As an experienced appliance repairer, I will guide you through the troubleshooting process, from the simplest fixes that even a novice can handle to more complex issues that might require professional attention. Let’s explore the common causes of this problem and the steps you can take to diagnose and resolve it.

Lint Buildup

Lint buildup is the most common culprit of a burning smell coming from your dryer. Lint burning smells like burning hair, but a rubber belt burning will smell the same. Over time, lint can bypass the lint filter and accumulate within the dryer’s ducts. The older your dryer, the more likely it is that significant lint has built up. Occasionally, a piece of this accumulated lint may break off and fall into the heater, where it burns up. Typically, these pieces are so small that you might not even notice them. If you’ve recently taken a dryer out of storage and noticed a burning smell upon first use, this is fairly normal. Lint that has dislodged over time or due to movement may now be passing through the heater.

Prevention is the best approach here. Regular maintenance of your lint filter can significantly slow down the buildup of lint, though some accumulation is inevitable. The more lint that passes the filter, the more you will find in the heater eventually.

What To Do:

- Inspect your lint filter: Ensure the lint filter has no holes or cracks. Replace it if necessary; having a spare is always a good idea.

- Vacuum the ducts: Use a vacuum to remove as much lint as possible from the dryer’s ducts. Be thorough but gentle to avoid damaging any internal components.

- Monitor the dryer: After cleaning, it’s common to still detect a slight burning smell as any dislodged and unvacuumed lint clears out. This should decrease after a few cycles.

- If the smell remains, or the dryer isn’t turning or heating, proceed to the next step.

Motor Capacitor Failure

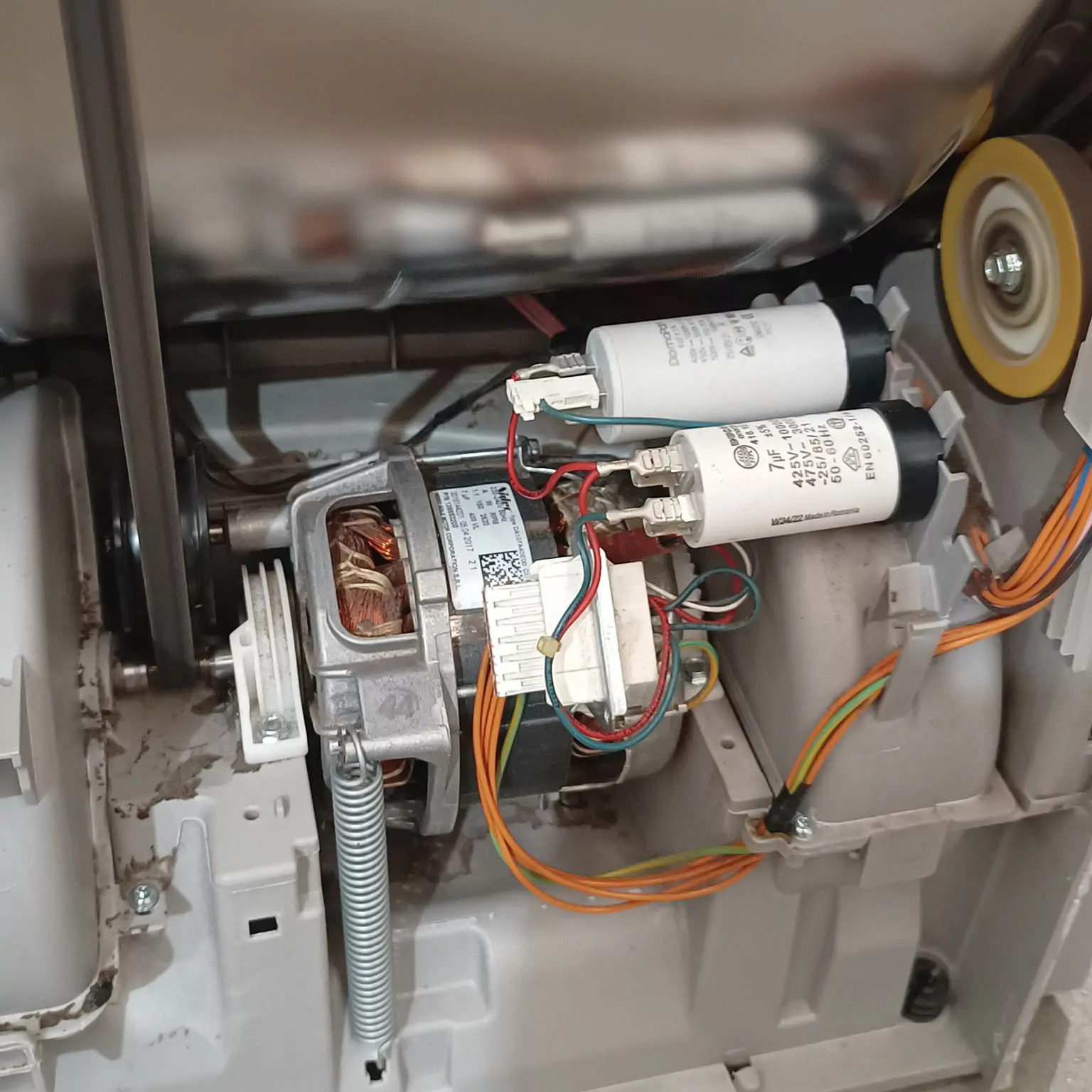

The motor run capacitor in your dryer is essential for helping the motor start and operate smoothly. To oversimplify its role – and not entirely accurately – you can think of it as a rechargeable battery. This “battery” doesn’t power the motor for extended periods but is crucial for delivering the quick burst of energy the motor needs to kickstart. Over time, similar to a rechargeable battery, the capacitor loses its capacity to hold a charge. If the charge becomes too weak, the motor that turns the drum will struggle to start turning. You might find yourself manually helping the dryer start by giving the drum a push before quickly closing the door. As the capacitor’s condition worsens, the drum might not turn at all, even when empty. In such cases, attempting to start the dryer might result in a buzzing noise from the motor area, but no physical movement – a clear indication that the capacitor might need attention or replacement. Usually when a capacitor is failing it shows no outward signs but if it fails catastrophically and blows a hole out its side or top, usually accompanied by smoke and a burning smell, and often tripping the safety switch as it shorts out internally. Smoke from a burning capacitor will usually smell acrid – like plastic burning. If the drum is not turning its also possible that other components are overheating like the heater or motor which is contributing to a burning smell.

What To Do:

- Access the Capacitor: This task requires a bit more expertise, as you’ll need to open your dryer to access the dryer’s motor. First, unplug the dryer for safety. Generally, you will need to remove the top of the dryer by unscrewing two screws at the back (and occasionally a hidden screw at the front of the machine) and sliding it backwards. Then, unscrew the right side panel when viewing from the front. The motor run capacitor is typically located near the motor or attached to it.

- Identify the Motor Run Capacitor: First, ensure your dryer is unplugged and safe to inspect. Locate the motor run capacitor, which is usually attached near the motor. It’s typically cylindrical in shape with 2 or 4 terminals and a bit bigger than a D size battery. Not all motors have capacitors either so if you can’t find it, you might not have one. Do not get confused with an EMI filter which looks very similar to the motor run capacitor. If fitted, it can usually be found close to where the power cord enters the dryer and is usually labelled as an EMI filter.

- Look for Visible Damage: Check the capacitor for signs like bulging, leaking, or a burnt smell, which indicate failure. These are clear indicators that the capacitor has failed, but capacitors can, and usually do fail internally without any external signs.

- No Multimeter: Testing the capacitor with a multimeter is ideal for diagnostic purposes, but if you don’t have access to one, it can be simpler to just replace the capacitor. Aftermarket capacitors typically cost less than $10 each and tend to wear out over time anyway, also affecting the motor’s efficiency. These capacitors typically feature universal connections with blade terminals, making them easy to replace. However, be aware that some manufacturers use custom mountings to compel the purchase of their genuine, and often much more expensive, and often inferior replacements.

- Replace if Necessary: Replace the capacitor if testing confirms it is faulty. Ensure the replacement matches the original’s specifications in capacitance and voltage. Connection orientation doesn’t matter for motor capacitors because they are non polarised but ensure correct wiring if dealing with multiple capacitors.

- Consider Professional Help: If you are uncomfortable performing these tasks or unsure about the diagnosis, consider hiring a professional. Handling electrical components can be hazardous without proper expertise and safety precautions.

Belt and Guide Wheel Issues

After capacitor problems, issues with the belt and guide wheel are the next most common cause of a burning smell in dryers. These components are critical for the smooth operation of the dryer, and both can be accessed near the motor capacitors, allowing for convenient inspection.

The guide wheel, typically made of plastic with a metal core, supports and guides the dryer belt as it rotates the drum. It helps maintain the belt’s alignment and tension, ensuring efficient movement. Over time, wear and tear or manufacturing defects can cause the guide wheel to deteriorate; it might even begin to melt if the friction becomes too great. This deterioration can cause the belt to misalign, fray, and eventually burn, leading to a noticeable burning smell.

Depending on the dryer model replacing the belt and guide wheel can vary in complexity. In many vented dryers, the process is straightforward, but in other models, particularly condenser dryers and heatpumps it may involve removing the motor, and feeding the belt between the drum and the housing without damaging it, a skill that is learned with practice.

What To Do:

- Release Tension: Before inspecting, use a pair of pliers to release the tension on the guide wheel by carefully unhooking the motor spring.

- Visually Inspect: Check the guide wheel for signs of wear such as melting, cracking, or delamination of the plastic from the metal core. For the belt, look for fraying, thinning, or any signs of burning.

- Test the Guide Wheel’s Integrity: Manually spin the guide wheel to ensure it rotates smoothly without wobbling or sticking. Irregular movement can indicate internal damage, suggesting replacement is necessary.

- Assess the Belt Condition: Feel along the belt for any rough patches, thinning areas, or signs of heat damage like brittleness or discoloration.

- Replace if Necessary: If you find any issues during your inspection, replace the parts. For the guide wheel make sure you clean the shaft very well and that the new wheel spins freely. Sometimes the shaft needs to be sanded down to remove scratches and gouges caused by the bad guide wheel. And, let me give you an insider tip. You can usually get away with running a pretty messed up, frayed, cracked belt for many years on a good guide wheel. If you have a bad guide wheel it will trash a brand new belt in no time flat if the dryer will run at all.

- Consider Professional Help: Given the complexity involved in some models, particularly those requiring motor removal, it might be wise to hire a professional. But if the appliance is going to the bin otherwise, you might as well give it a go and learn something.

Other Potential Sources

There are many other potential sources of a burning smell in a clothes dryer, but the above will cover off 95% of them. The other 5% are many and varied but will cover things like:

- Failed electrical components on the control board or otherwise

- Burned out wiring that has overheated or been abraided

- Heating element issues

- Drum seals becoming sticky and causing too much friction

If your burning smell is caused by one of the above it is a more specific problem that requires more specific advice tailored to your model. They are also more difficult to identify and diagnose, but if you can see a sooty burn mark you’re probably in the right place!